Featured

Wind Turbine Failure Rates

Wind Turbine Failure Rates. However, turbines still see failure rates of more than one failure per turbine per year [1]. The reliability data, including failure rate and downtime,.

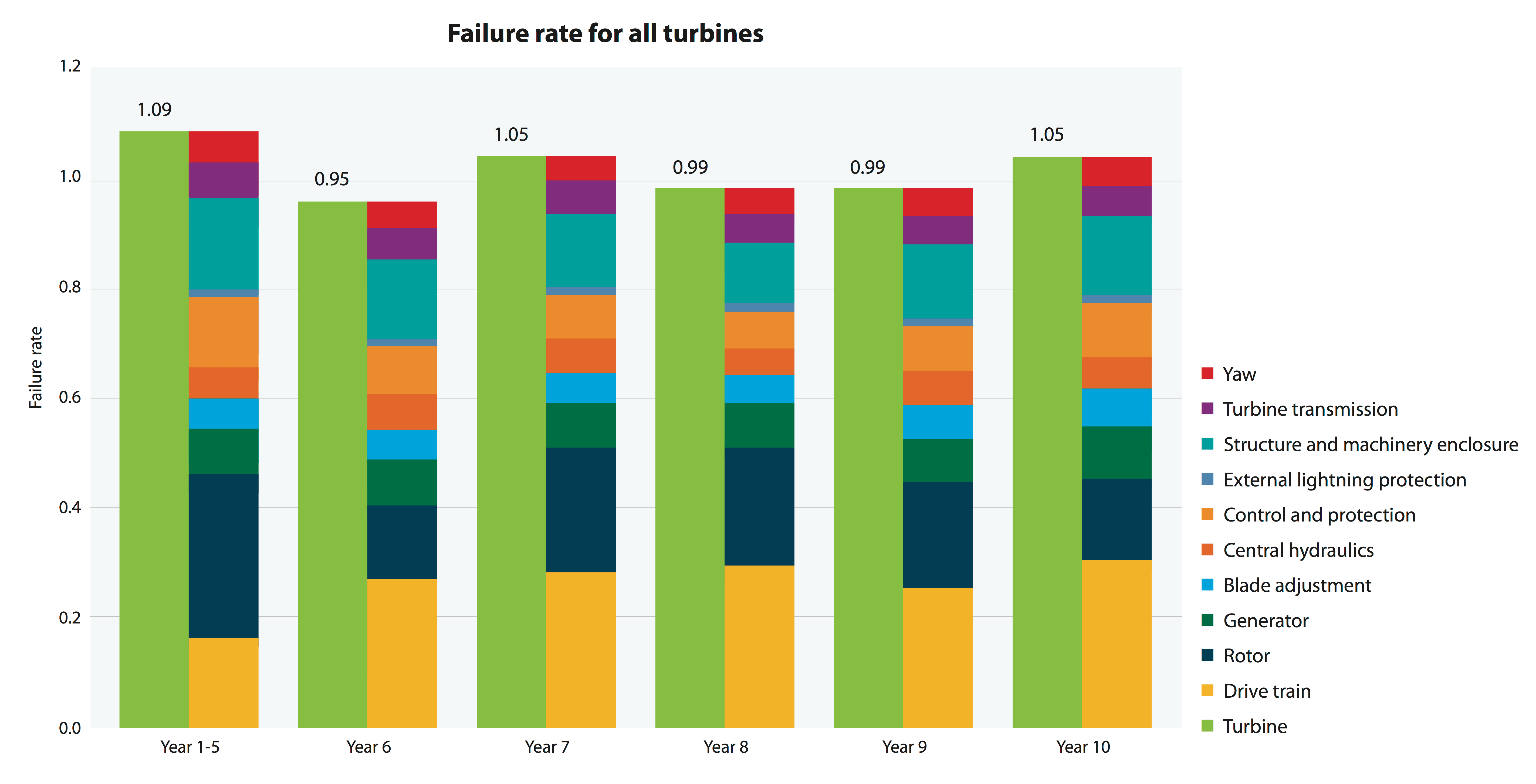

This is true for the older turbines under 500 kw and for the 500/600 kw class. It is the same formula used in:7,8,11 λ ¼ ∑i i ¼1∑ k k ni;k=ni ∑i i¼1ti=8760 (1) where λ = failure rate per turbine per year The graph below shows major component failure rates for all types of turbines in our dataset during the first ten years of operations.

There Are 55 Active Wind Power Stations Over A Huge Area.

The failure rate is the reciprocal value of mean time between failures (mtbf). It is the same formula used in:7,8,11 λ ¼ ∑i i ¼1∑ k k ni;k=ni ∑i i¼1ti=8760 (1) where λ = failure rate per turbine per year The average failure rate for an offshore wind turbine from this analysis is 8.3 fa ilures per turbine per year.

Wt Failure Rates And Downtimes, Broken Down By Subassembly, Are Collated From 18 Publicly Available Databases Including Over 18 000 Wts, Corresponding To Over 90 000 Turbine‐Years.

Different failure modes have different repair times, ultimately leading to different costs. It is clear that the failure rates of the wind turbines (wts) now installed have almost continually declined in the first operational years. In the figure above, the average annual failure rates for the different technical concepts are presented.

Typically, A Higher Failure Rate And Greater Repair Resource Requirement (I.e.

This indicator shows how reliable your wind turbine or its specific components are. The reliability of wind turbines has improved over time. The drivetrain of the turbine is a major contributor to failure rates with the power electronic converter, the generator and the gearbox account for about 0.2, 0.1 and 0.1 failures per

They Concluded That Wind Turbines Were Achieving Reliability Better Than.

The graph below shows major component failure rates for all types of turbines in our dataset during the first ten years of operations. In almost all components of the wind turbines of the variable speed concept have the highest failure rates. The problem with wind turbine blade failure rate is that 99.9999% of blade cracks or blade manufacturing defects that propagate into structural cracks are detected before catastrophic failure.

Most Of The Wind Turbine Oems Are Starting To Have Enhance Condition Monitoring Systems That Can Detect Blade Cracking And Warn Before Catastrophic Failure.

Considering failure rate and downtime for onshore wind turbines in japan. In most cases, a trend observed toward higher failure rates with increasing complexity of the technical concept. Consequently, wind farm developers try to select

Popular Posts

Ifb Washing Machine Top Load Gearbox Price

- Get link

- X

- Other Apps

Comments

Post a Comment